Aircraft Development

Contract Manufacturing

Transform the vertically integrated drone industry

into a horizontal division of labor

Deliver valuable manufacturing solutions

The greatest strength of VFR is its comprehensive service from development support, procurement, contract manufacturing, sales and maintenance.

We inherit the know-how of electrical equipment, automobile and aircraft manufacturers that have supported Japanese industry and realize product safety standards at the highest level.

Mass Production

DevelopmentManufacturing Achievements

VFR started as a subsidiary of VAIO, and our greatest strength is the mass-production development and contract manufacturing of hardware and modules, based on which, we provide a one-stop service for safe airframes that meet strict safety standards and peripheral devices and services such as drone ports, while incorporating the knowledge of DRONE FUND, that advocates a “drone and air mobility based society”, and domestic automobile manufacturers that have supported Japanese industry.

Inheritance and Application

To realize the utopia of value creation

Drones are also known as “flying computers,” thus it requires extremely precise computing and robotics technologies for the development. We effectively utilize the advanced design and manufacturing technologies, the management capabilities of supply chains worldwide, and other skills that are cultivated in the PC business, and provide aircraft, components and related solutions with high availability and cost performance to drone users and drone business operators.

We effectively apply advanced design and manufacturing technologies, supply chain management capabilities, and other skills cultivated in the PC business to drones and supply components and related solutions that enable drone manufacturers to provide highly available and cost-effective aircraft to drone users.

We are committed to applying the highest level of “monozukuri” (excellent product creation) to the field of drones, from design and development to procurement, integration, quality assurance, delivery, and after-sales support. Moreover, we provide optimal solutions through co-creation with drone operators, service providers, and end users.

There is a mass production manufacturing base within Aero Corporation that handles the entire assembly process, from the construction of airplane structures to painting and outfitting assembly. They have inherited expertise in thorough quality control from the PC, automotive, and aviation industries, ensuring the highest level of product safety standards.

| Problems to be solved | Solution by VFR |

|---|

| 01.Specification | |

|---|---|

| Design not considered mass production | Optimize the mass production process based on drone manufacturing experience |

| 02.Parts procurement | |

| Small lots make parts procurement cost high | Utilize parts procurement know-how inherited from VAIO’s PC business Cost reduction by common parts among multiple drone makers |

| 03.Assembly | |

| Not having a system to realize mass production | Realize stable assembly with drone assembly history and dedicated factory and stable production by coordinating multiple plants |

| 04.Flight test | |

| Difficulty in securing a place to fly drone | Place for flight test where does not require reservations |

| 05.Packing and shipping | |

| Lacking know-how to safely deliver bulky products | Design appropriate packaging method for each drone of various shapes |

| 06.Distributor Sales | |

| Demand does not reach to the mass production level | Provide a configurator that can customize drones online and information on subsidies/grants to promote sales as an agency |

| 07.Customer Service | |

| Phone and email correspondence on individual level | Manuals and FAQs accessible from a PC or smartphone lead to quick answers in situations where immediate solutions are required |

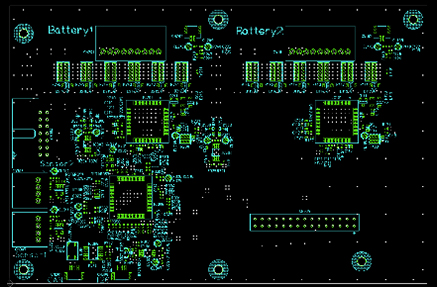

[Electronic Substrate Consignment Development]

Module Development by VFR

Contract production services for electronic equipment

“High-level implementation achieved with technology cultivated in the PC industry”

We develop and manufacture hardware from a small number, such as the development of substrates for drones.

Industry-proven mounting machines are used for production.

Supporting process from development of drone exclusive substrates to mass production is VFR’s strength.

“Achieve both high flexibility such as small lot handling and high quality”

We undertake design support, substrate development and manufacturing consignment on the premise of mass production of drone video transmission modules, flight controllers, GNSS, etc.

“We solve various problems in the drone industry.”

We dramatically shorten the delivery time and provide one-stop service to the customer support.

We accept orders from domestic and overseas manufacturers.